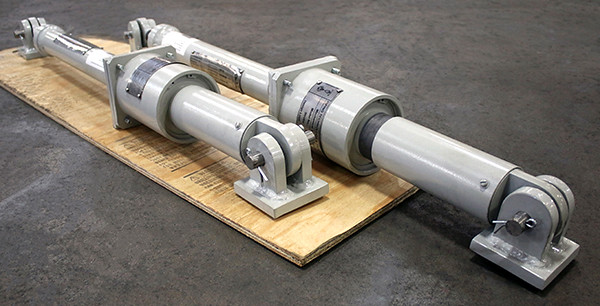

| Type: | Variable Spring Supports |

| Size: | Accommodate Elevation Difference up to 11′-5″ |

| Material: | Carbon Steel | Hot-dipped Galvanized |

| Design: | 20,000 lb. Load | 4,700 lb./in. Spring Rate |

PT&P designed and manufactured over 50 variable spring supports for a propane dehydrogenation (PDH) unit in Texas. The components, including the spring cans, rods, welded beam attachments, turnbuckles, and clevises, were fabricated from hot-dipped galvanized carbon steel to ensure durability and corrosion resistance. These variable spring supports are engineered to accommodate an elevation difference of up to 11’-5″ from the bottom of the steel structure to the pipe connection. They are designed to handle an operating load of 20,000 lb., with a spring rate of 4,700 lb./in., and facilitate a 0.007″ upward movement. Each support underwent standard load testing before being shipped to ensure they met the required specifications and performance standards.

In addition to spring supports, PDH units require other products from the Piping Technology and Products portfolio. Our field service team regularly works with PDH units by doing inspections and fine-tuning the supports because of the heavy loads the equipment requires. The experience of our team coupled with the knowledge and access to our specialized tools and equipment has clients calling us on a regular basis.

Spring supports are one example of what we can provide, but we also have designed and manufactured floating rings, fabric and metallic expansion joints, slide plates, constant supports, and fabricated pipe shoes, guides, and anchors in PDH units. PDH plants have the unique challenge of having high-temperature requirements.

Increasing demand for propylene in various industries such as automotive, packaging, and construction is driving the growth of the PDH unit market. Propylene is a key ingredient in the production of various plastics and synthetic materials, which are in high demand globally. Rising investments in petrochemical infrastructure in emerging economies, particularly in Asia-Pacific and the Middle East, are creating new opportunities for PDH unit manufacturers. The increasing demand for petrochemical products in these regions is driving the installation of new PDH units.

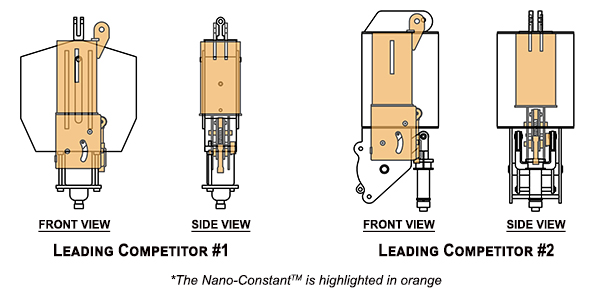

Variable spring supports are widely used in various industrial applications where pipelines, equipment, or structures experience vertical movement due to thermal expansion, weight changes, or other dynamic loads. Some common applications are heat exchangers, reactors, steam pipelines, high-temperature piping, and pumping stations to name a few. At PT&P, we specialize in designing and manufacturing custom variable spring supports tailored to meet the specific needs of both new plant constructions and retrofitting projects. Our expertise extends to creating custom solutions that seamlessly integrate into existing applications in older plants, even when the design is based on a competitor’s model. This flexibility ensures that our clients receive the optimal support system for their unique requirements, regardless of the plant’s age or existing infrastructure.

PT&P REF. ORIGINAL POST 11062018

Read More