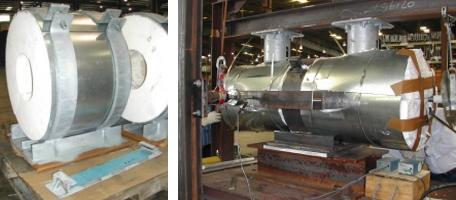

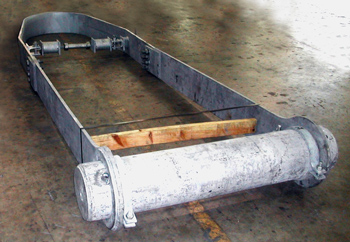

Piping Technology & Products, Inc. designed and manufactured two custom built variable spring assemblies using heavy duty spring coils and fabricated hardware components.

The loads, as specified by the customer, were greater than the maximum operating loads for our largest (PT&P size 220) standard variable springs. In order to meet the customer’s requirements, a custom variable spring was designed and fabricated using a larger spring coil normally used only in constant spring assemblies.

The specially fabricated variable spring was 20 in diameter with a standing height of 51 and the hanging components (rod, turnbuckle, clevis) were 3 1/2 diameter pieces. The spring rate was 3232 lb./in. All the pipe hanger assembly components were made from carbon steel.

The installed (cold) load was 58,000 lbs. and the operating (hot) load was 61,700 lbs. The calculated movement from cold to hot was 1 1/8 down. The variable spring was tested in the load cell to insure proper operation and also to set the cold load to the specifications provided by the customer.

Do you see a need for variable springs in your piping system? Get pricing today!