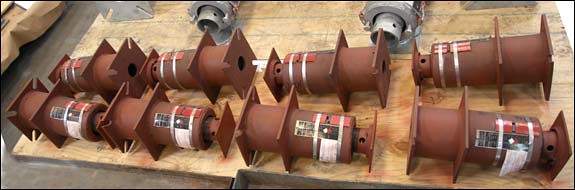

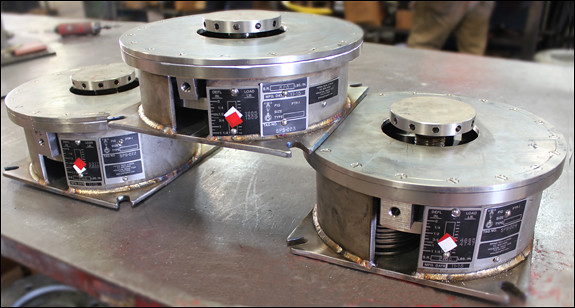

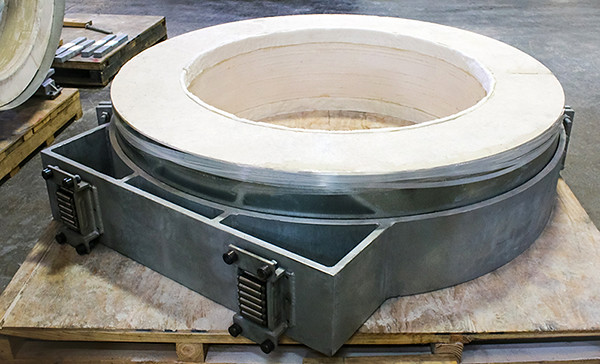

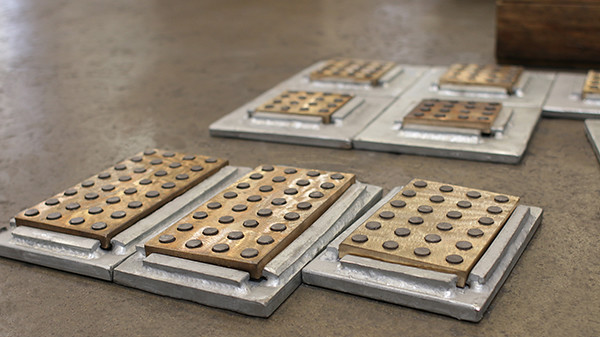

| Type: | Constant Springs & Alloy Clamp Assemblies |

| Size: | 48″ H x 57″ L x 24″ W | 36″ dia. Clamp |

| Materials: | Carbon Steel with HDG Finish | Alloy |

| Design: | 1070°F | 7-1/2″ Total Travel | 24,712 lb. Load |

| Testing: | Load and Travel Test |

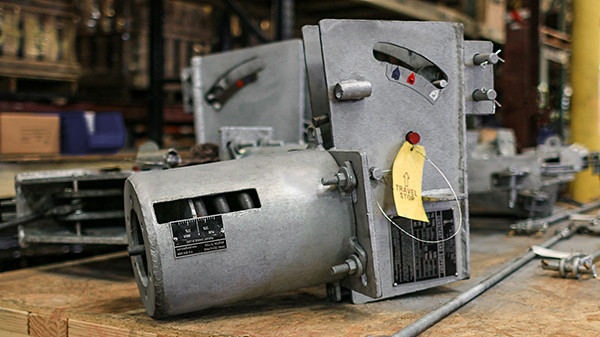

PT&P custom-designed and manufactured constant spring supports for a mainstream system at a power plant in Egypt. The constants include alloy clamps designed for a 900 mm (approximately 36″ dia.) pipe. They are 48″ H x 57″ L x 24″ W with 7-1/2″ total travel from the cold position. We also supplied alloy clamps designed for an operating temperature of 1070°F. The constants are fabricated from A36 carbon steel and include a hot-dip galvanized protective coating. They are designed for an operating load of 24,712 lb. The constants have been modified to accommodate a specialized spring coil and modified casing in order to fit the existing space or envelope. Standard travel and load tests were performed prior to shipping.

Constants can be used with rollers, travelers, or slide plates to accommodate lateral or axial movement in the pipeline system in plants such as solar, geothermal, soybean crushing, ethanol, and other green energy facilities. Our company and its subsidiaries work with over 90% of the leading green energy providers in the world.

Our Field Service team, along with our pipe support engineers and designers, can also conduct inspections of existing supports, provide consultation on-site remediation, and oversee installation on both a short-term and long-term basis catering to facilities worldwide. So whether a “grassroots project” or an existing plant that has been in service for years, we offer cost-effective products and services.

PT&P REF. ORIGINAL POST 10092018

Read More