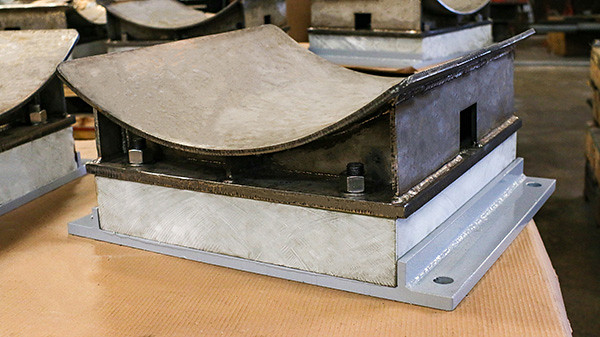

36” Dia. Cryogenic Pipe Saddles Designed for an LNG Facility

PT&P custom-designed pipe saddles with micarta base insulation for an LNG facility in Australia. The saddles were fabricated from 304L stainless steel plates with thickness ranging from 1/8″ to 3/8″. The micarta blocks range in thickness from 1/4″-3″. The saddles were designed to support pipes up to 36″ in diameter at an operating temperature of -300°F. Standard Q.C. and dimensional tests were performed prior to shipment.

A pipe saddle is any pipe support that cradles a pipe and transfers the pipe’s load weight onto a supporting base. Much like a saddle on a horse supports a rider and keeps them from bouncing on the animal, pipe saddles support a pipe’s weight. Pipe saddles are commonly used on large-diameter piping where the load is exceptionally heavy or when contraction-expansion movement is expected. Pipe saddles are welded to the pipe and are used in conjunction with roller supports or on-beam supports.

With the current uptick in global LNG demand driving US-based LNG production, Piping Technology and its subsidiaries are well-positioned to support large-scale projects in a timely manner. Our engineering and production teams work closely with our clients to ensure site, operator, and design needs are met. LNG demand is positioned to continue to grow over 60% by 2035.

PT&P REF. ORIGINAL POST 10232015

Read More